|

|

|||||||||

|

|

|||||||||

|

|

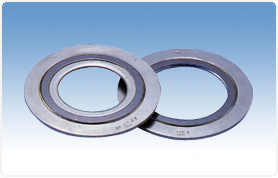

The spiral wound gasket is a type of semi-metallic gasket, rationally designed to provide a high perfor mance in use at high temperature and pressure. It is equipped with an ample compressibility and an increased demand has been seen in these years because of the merit that a gasket seating stress can be controlled by an optimum compression thickness. It is widely used at process line and lines handling heating medium in oil refineries and petrochemical plants as well as steam processing lines in thermal power stations, atomic power stations and vessels of steam turbine engines. It is made of V-preformed thin metal strip and a selected filler material which are tightly and spirally wound together with only metal strip wound in several folds and spot-welded at the beginning and the end of winding. |

|